Industrial welding

Pimas has been developing complete arc and resistance welding systems since it was born, more than 30 years ago, and can offer customized and versatile solutions for all the processes.

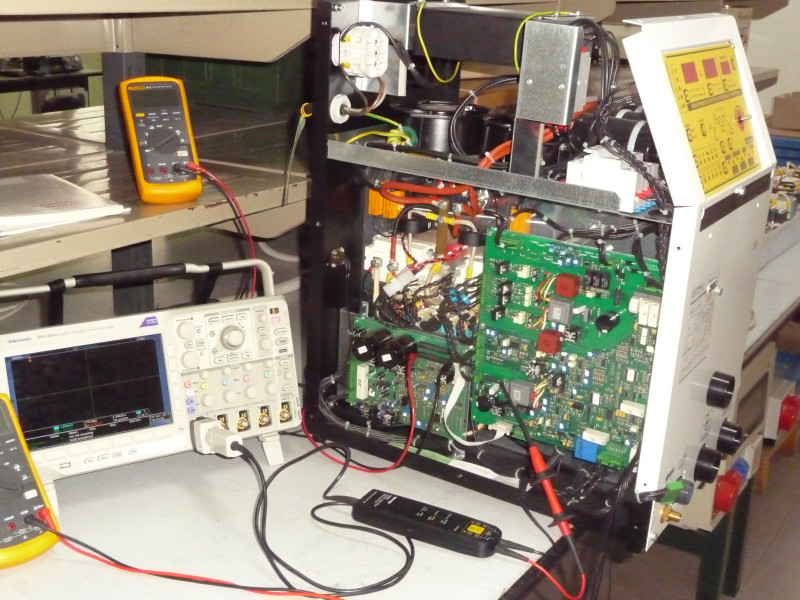

Compact and highly reliable, Pimas generators feature modern technology, full-digital control and a rich set of process parameters.

As for the human-machine-interface (HMI), several solutions are possible, ranging from LCD panel to "touch" technology.

Welding machines for special processes are possible too, for example:

- Continuous tube welding;

- Submersed arc welding;

- Superficial treatment.

Arc welding

Thanks to the efforts that have been made in the last years, Pimas has extended the performances of its arc welding generators up to 200kHz switching frequency for currents up to 500A, with many advantages in terms of welding precision, noise and pulse frequencies.

Pimas offer high-tech solutions for any welding process:

- Mig/Mag

Full-digital control, outupt currents up to 500A.

Solutions with tyristor electronic control are also possible.

- Tig

Full-digital control, output currents up to 300A.

Solutions with tyristor electronic control are also possible.

- MMA

Full-digital control, output currents up to 400A.

Solutions with tyristor electronic control are also possible.

Resistance welding

Control, power and interface sections for the 2 kind of technologies:

- inverter

wide frequency range, from 1÷2kHz up to 15kHz, and primary current in the range 200÷1600A.

- AC mains

Open-loop or constant current control, for single-phase and three-phase systems.

Plasma

Portable inverter generators up to 30A, with air compressor inside.

Inverter generators up to 150A